Some Known Questions About Hot Runner Systems.

Parts made by the use of a Valve Entrance usually have the least frozen-in anxiety, without any sprue, and no noticeable flaws. Shutoff Gates can produce constant shot-to-shot repeatability, faster cycle times, good automatic mold operation as well as bulk high quality. Shutoff Gated molds are as a result, ideal for automated high volume manufacturing.

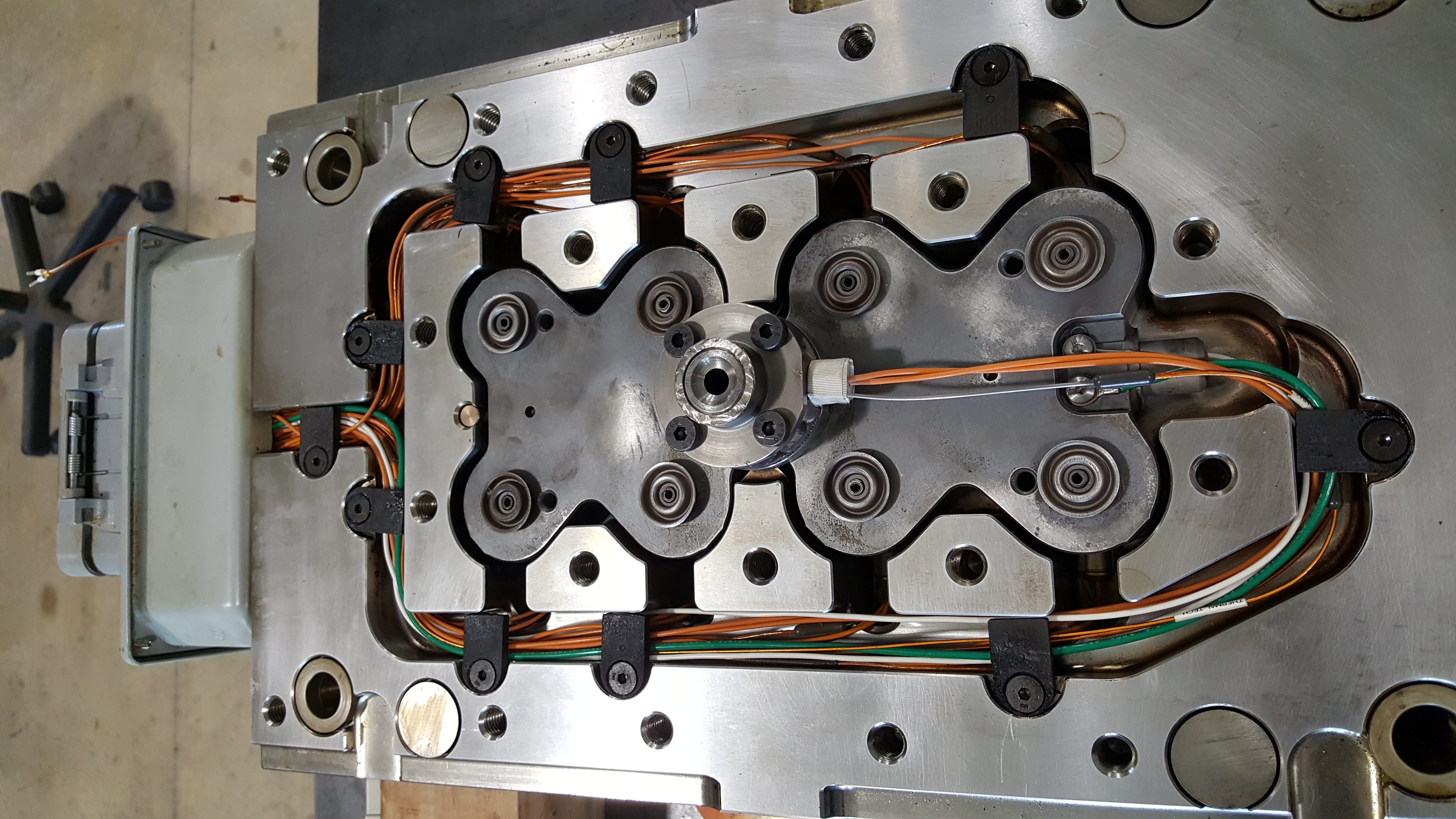

MDi's Single-Cavity Valve Gates include the very same ingenious gating modern technology utilized in our multi-cavity Hot Runners. Pile molding requires less space Makes use of smaller equipments, which causes lowered run prices Produce twice as numerous parts without raising press size/tonnage Boosted output efficiency Fewer equipments needed Several component designs created simultaneously Conserve time and also cash by producing several components at the same time Decreased waste A Stack Mold capitalizes on Newton's third legislation of movement, in that the contrary force required to infuse a single face is currently utilized to mold a 2nd set of components.

MDi supplies Shutoff Gate Stack systems in any kind of setup to make sure that the customer attains the maximum tooling service for their application - hot runner systems. MDi uses premium quality, high performance systems that likewise sturdy and also reputable, provided promptly, competitively priced and also feature MDi's cutting-edge nozzle and also manifold innovation. MDi is a world-leading American producer of Hot Jogger systems as well as components with the ability to establish personalized and cutting-edge remedies for plastics Shot Molding.

All of our parts are in-house made and also produced in our facility at St. Charles, IL, with a concentrate on top quality and integrity (hot runner systems).

When a mold and mildew opens up, the product commonly "drools" out as a result of pressure in the system. This could make up an incredible quantity of product shed gradually, which can be costly, particularly in high manufacturing tools. Usage of the Anti-Drool Sprue Bar Tool causes an extra lasting, cleaner as well as reduced maintenance system reducing downtime due to clean-up.Discover more >.

The Single Strategy To Use For Hot Runner Systems

The i VG ™ does well under one of the most requiring processing conditions. Unlike electric shutoff gates as well as standard pneumatically-driven cylinders, that can stop working in very hot operating settings, the inner shutoff entrance executes at temperatures as much as 400 ° C. Rheo-Pro ® i VG ™ inner shutoff entrance nozzles with a piston inside the nozzle body are clean, small, and cooling-free.

Warm jogger mold and mildew VS Two plate mold and mildew VS Three plate mold and mildew Refers to the section between the mold inlet and the product gateway. The liquified plastic is kept streaming in the runner under the effect of the shot stress as well as its own heat. The runner just operates as part of the molding material, yet is not a component of the last item.

Hot Runner Systems Can Be Fun For Everyone

The cold jogger is able to decrease the acrylate or polycarbonate utilized for light transmission in the shot mold and mildew jogger, so regarding stay clear of the visible strips triggered by the injection molding in some parts. Drawbacks of the cool runner: (1) Extra waste of resources; (2) Additional actions in the entire manufacturing procedure; the cold runner mold and mildew consist of two collection mold and mildew: 2 plate mold and mildew and three plate mold Two plate mold and mildew: When the mold and mildew opens up, the tooth cavity plate and also the core plate are separated to release the molded product.

Being most commonly made use of, it is the most basic and the majority of standard type of the injection mold, and can be created as a single-cavity or a multi-cavity injection mold. 3 plate mold Three plate mold has two parting surface areas. Compared to two plate mold, it adds a partly movable intermediate plate (also called a movable jogger plate, on which eviction, runner, in addition to various other components and also parts needed for the core are created) right into the dealt with mold fifty percent, so it is additionally called a three-plate (dental caries plate, jogger plate and also core plate) shot mold and mildew, which is often made use of for the single-cavity or multi-cavity pinpoint gateway plastic injection mold and mildew. hot runner systems.

The 3 plate mold and mildew includes a challenging structure, a high manufacturing cost, and also challenging component handling, so generally it is not used for shot molding of big or additional big plastic items As an usual component of the shot molding system, the hot jogger ensures that the plastic product in the runner and also gate keeps the molten state by heating.

view website hop over to here click here to read